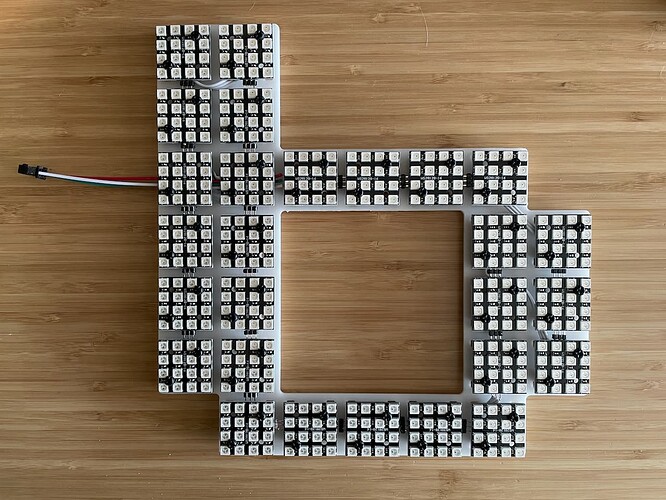

The 4x4 matrix I used is basically like this one - 4x4 matrix, aliexpress although its about 50% more expensive now… i got them for $0.85 each. might be good to shop around, and pay attention to shipping costs.

the 4x4 panels measure 30mm square.

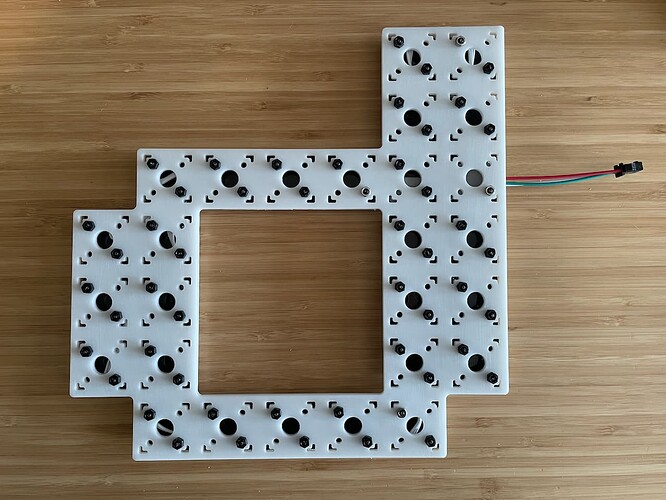

building a jig is essential. i had to iterate on the jig a few times to find one that worked. i originally tried 3D printing one but it wasn’t precise enough (flat enough) and required too much clean up, then i moved on to laser cutting a slab of delrin.

then you can see i am bridging the gaps with header pins. they’re exactly the right spacing and length. for corner turns and u-turns, i had to cut wire lengths. the input begins in the middle of the letter, and dont forget to add power injection. i found adding power injection with a heavier gauge cable at the last tile worked just fine.

this is the completed letter. so after screwing it upside down in the jig and soldering all the connections, it can receive a custom cut delrin sheet backing that holds everything in place, and as a bonus, serves as very solid protection of the wiring

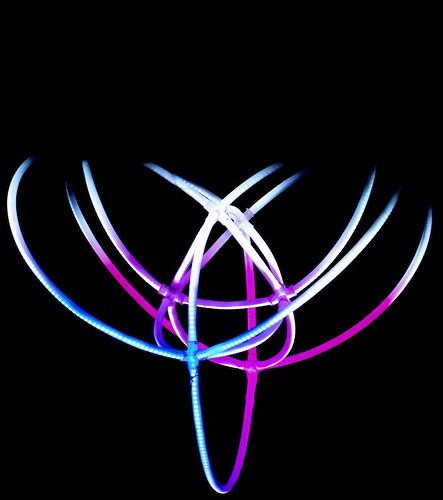

lastly - i laser cut some 15% black diffuser acrylic and 3D printed the letter shells.

@hex337 - the LEDs are about 27mm from the bottom of the diffuser acrylic. that was the closest i could bring it without the individual LEDs beginning to resolve into their own spots.

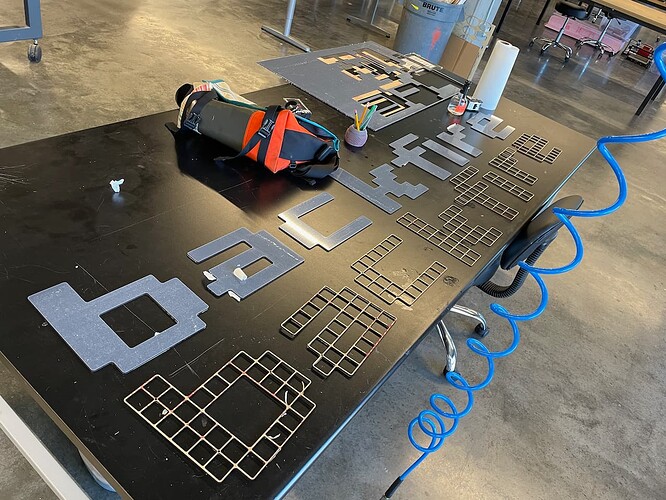

At this point I was seriously running out of time to finish before leaving for the playa. So I hastily built the display case. I printed out the back of each letter’s jig as a drawing and taped them together to make a template where I could drill all the necessary holes for mounting them and running the wires through.

The backing sheet is a new material I’ve discovered, its called ACM aluminum composite material, which is two thin sheets of aluminum with a plastic composite core. (about 3mm thick) - it is basically the same material used in road signs! Its really super easy to cut and drill with power tools and its quite robust. you can pull the protective film off and get a very nice clean white surface.

And thats basically the build process. I was going to write up something to post on my website, but I still havent gotten around to it!