Okay I ended up going with some WS2815 from what appears to be a reliable seller. Here is my final plan, interested in your thoughts.

Looks great to me! I don’t typically fuse my AC inputs like that but there’s no harm in doing it and it might provide some additional protection in some scenarios.

going to share a final wiring diagram later on with some questions.

Had to go with the pro expander as the ws2815 strips I chose are 12 v. definitely have a few questions about wiring it all together. I have never used an expansion board before. More in a couple hours

Okay here is what I think will be final…until you point out oversights. ![]() what am I missing if anything? The only part I am confused about is the grounds? are they correct with the strips, expander and PB to give proper reference voltage? Also with the use of the power strip on AC side and the Pro expander I am able to cut out quite a few fuses as the Pro is fused to my needs. Thoughts?

what am I missing if anything? The only part I am confused about is the grounds? are they correct with the strips, expander and PB to give proper reference voltage? Also with the use of the power strip on AC side and the Pro expander I am able to cut out quite a few fuses as the Pro is fused to my needs. Thoughts?

Anyone??? Anyone??? Crickets?? ![]()

I think it looks good, but depends on the size of the power supply and what you need the bus for. My setups are similar, but I don’t use a bus or sensor board. I just use a power supply → expander board w/PB attached → runs of pixel strings connected to expander board terminals(w/fuses). I also don’t inject power.

Hey thanks for the reply. The PSU is 400 Watts and 12 volt.

I was using a bus board for power distribution as I thought is was required for safer operation, but if i don’t need to and can just run power into the pro expander then I am all for it. I just wasn’t sure what the pro expander could handle power wise. I believe the pro expander will reduce the 12 volts to the voltage needed for the pixelblaze correct? And the Pixleblaze connects to the sensor board so that should greatly reduce the complexity of my electronics box. Planning to start building this weekend.

The pro output expander is rated to distribute 15A, so I wouldn’t go over that. If you have three outputs being used, you could use 3 x 5A fuses. I’ve never run them that close to max though. There are some decent 400w (200w per) dual output power supplies on Amazon. The single out from that supplies 16.6A, so you would want to limit how much would flow through the Pro Ex. Then you could use the other output to inject power down the line of your build.

Yes, the Pro Ex will convert the 12v input to power your PB. Big advantage to the Pro Ex is that it does make your builds much cleaner and easier. I use them with every build and they are very reliable. They’ve survived power surges, water penetration, reversed wiring… you name it. If it can be broken, I will break it ![]() but so far the Pro Ex and PB have been very solid. Some of my oldest builds are at 5-6 years now, in enclosures outside. The weather here goes from -40 to +40 and they are still running.

but so far the Pro Ex and PB have been very solid. Some of my oldest builds are at 5-6 years now, in enclosures outside. The weather here goes from -40 to +40 and they are still running.

Hmmmm,

I guess I’m looking for recommendations about what to do next then. I already have the power supply and need to use instead of replace as I am already deep in to this project. The power supply output is 33.3 amps, this sounds like a problem for the ProExpander (PE). The power supply can be set to 75,50 or 25% manually with dip switches. I have chosen WS2815 strips specifically to avoid power drop and down line injection as it is not convenient for the installation.

So my question to everyone is how do I make this work? If I had two or three power supplies one for the strips via a bus board and one for the PB, would that work? I need the beefy power supply as i have 4.4. meter runs off LED strips, I need the PE to duplicate the signal of the PB to multiple strips simultaneously. How do I make this work?

Wait hold on…I occurs to me you might have been saying something that just landed. The PSU is 33 amp but has two outputs, which i assume means each is half the 33.3. So I could use one output to link to the strips and the other output to the PE. Assuming the PSU is 90% efficient that would put my total output at just under 30 amps or 15 per channel. So there is that, also could just change out the 15 amp fuse on the expander to a 20amp? Just thinking out loud here, let me know if this is all completely off base, full of bad math or assumptions or just plain bonkers.

I would keep the 15A fuse on the Pro Ex, and yes you could use one output to run power through the Pro Ex. I would check to see if the powers supply actually supplies only half per output.

Or you connect the power to your strips like in your picture with the bus, but do not also connect the PSU to the Pro Ex input terminals. Connect a positive from one of your strips back to the Pro Ex and it will backfeed and power your Pro Ex.

I built a test box to try this out. In case I needed the controller in a location, but that location didn’t have easy access to power.

Okay I think one of these may work. I will try to search again for documentation on the PSU.

Hey just to clarify, if you have a 12V 400W PSU capable of outputting 33.3A, you won’t overload anything on the Pro Expander just by connecting it, even though the Pro Expander’s input is rated for 15A. What would happen if you accidentally draw more by having too many LEDs or driving them too bright is that the input side 15A fuse would blow.

Also, PSU efficiency is usually spec’d assuming the full rated output, so it’s more like if you were pulling a full 400W on the DC output side, a 90% efficient PSU would draw 400 / 90% = 444W from the wall.

Diagram looks good to me, except for what Matt said about being sure to fuse them independently if you do power injection to any part of the strip instead of running all current through the Pro Expander. Otherwise you’d be bypassing the fuses on the board so you could draw over the PSU’s max rating if you accidentally shorted an output. A good PSU will shut itself down (usually called overcurrent protection), but you don’t want to rely on that so you’d fuse the overall DC output separately, not relying on the fuses on the expander.

I think what’s missing here is we don’t know your final strip lengths and density. I’ll walk you through the power calculations assuming three 3.8m strips of 60/m WS2815. I’m using 3.8m because I think in your other messages you mentioned 2800 pixels at 720/m for that other COB strip, so that implies your piece is 3.8 m long.

3.8 m * 60 / m * 0.015 A per LED (typical for WS2815 = 3.42 amps max per strip (perfect, since it’s under the 5A max per pro expander output). The way to run power injection to the far side of the strip to prevent voltage sag is you’d use your beefy wires, but also connect them to the output of the pro expander (skip the bus thing). Then the whole strip is 5A fused. Note that

3 strips, one on each output = 10.3A total, all good because it’s under both the 15A spec for the expander and well under the 33.3 A max PSU output. And it’s even fine of you have two outputs on that PSU that were each capable of 200W (or 16.7A) max per output.

Hey @jeff Jeff and @mnielsen Matt,

Thank you both so much—over the last couple of days, I’ve learned a ton, and despite thinking I had a finalized design before, I definitely didn’t. But now, I do! Here’s how everything pencils out:

Power Calculations & System Design

I’m using WS2815 LED strips, which are 60 LEDs per meter and operate on 12V constant voltage. The full setup consists of:

Three strips, each 4.4 meters long

Each meter draws 18W, meaning each strip at full brightness consumes:

4.4m × 18W/m = 79.2W

At 12V, that comes out to 6.6A per strip

Total project draw at full brightness:

3 strips × 6.6A = 19.8A total

That’s obviously too much to run unrestricted, but since both the LEDs and the power supply are constant voltage, I can manage the system safely with a couple of adjustments.

How I’m Preventing Overload & Ensuring Safety

-

Power Supply Limiting – My power supply has DIP switches, so I’m setting it to 50% output to ensure I don’t overdrive anything.

-

Brightness Control – I’ll be capping the strips at 75% brightness max, which keeps each strip below 5A draw. That means:

6.6A × 0.75 = 4.95A per strip

Total system draw at this limit = 14.85A, well within my safety margins.

- Fuse & Circuit Protection – Since the power supply is dialed back and the brightness is capped, I’m confident that:

Individual channel fuses won’t blow.

The 15A fuse on the expander stays intact.

Final Setup

So, with these adjustments, I get a fully functional, high-performance system without the risk of overloading anything. The power supply won’t push more than I need, and as long as I keep brightness at 75%, I’m well within safe limits.

I’ll include a diagram to show exactly how I’m wiring everything. Let me know if you have any feedback or if I’ve overlooked anything—really appreciate all the help so far!

I am posting this now hoping you will see it today while I am doing the drafting and 3d printing for the power box so If i need to make any changes before wiring I will have time to do so and not rework.

Thanks again I really appreciate everything.

Diagram looks good.

I don’t think you need to limit your PSU to 50%. It won’t hurt, but might make troubleshooting brownouts difficult, especially if your two outputs are already 200W each, so limiting them to 100W could cause strange issues with the PB itself if the 5V output on the pro expander drooped as a result.

Just to really make this point, know that I regularly hook up a 300W 60A 5V supply to a PB and a strip of like 30 LEDs. If it’s in a permanent install, I fuse it appropriately.

Something we’ve all come to learn the hard way is that you can’t really trust the “Watts per meter” specs on strips. That 18W/m figure seems extremely suspect. The best option is to measure the draw yourself, but you can also get really close (and still be conservative) knowing some amps-per-LED figures; the go-to for WS2815 is to use 15mA per pixels. Therefore, a much more likely watts-per-meter is going to be 60 LEDs / m * 0.015 A per pixel * 12 V = 10.8 W/m. In real world scenarios with slightly less than ideal power injection, they’ll even draw less than this. And keep in mind, this draw is only when all pixels are at max intensity!

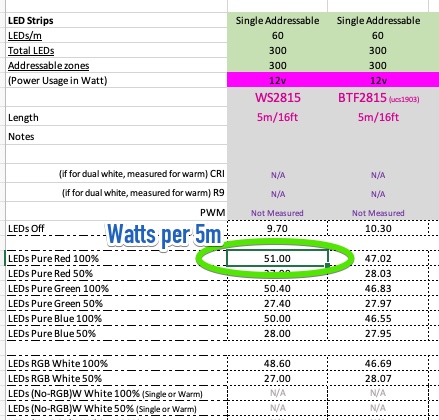

Another great source of real world measured data is QuinLED’s power spreadsheets. His LED-power-table_12v_v1.06.xlsx sheet shows that he measured WS2815 at max 10.2 W/m:

I still like your 75% max brightness in PB settings plan because I like to limit all strips to 80% - it prolongs their life.

Jeff,

Thanks for the reply! Glad this all makes sense to you also and thanks for the info about Quin’s! I found out my PSU is a constant voltage and, both sets of terminals are full power. Also good to know I don’t need to limit my PSU. Thanks a bunch and expect updates soon.

Much appreciated as I learn.

This topic was automatically closed 120 days after the last reply. New replies are no longer allowed.