I suspect the 6A limit is per strip, to keep too much current flowing through one part of the strip for a long segment and to manage heat buildup. Since you’ve split them up, you could drive them around 6A each without exceeding that.

If you are looking for off the shelf stuff, you could use multiple USB battery packs. Keep GND connected between them, and isolate multiple 5V zones to balance power. This can get bulky but the plus is things are easy to swap out. I made a coat with a dual supply like this.

Boost converters that work off of a 3.7V cell and output 5V, like used inside those USB battery packs, are one way to go, though it’s not easy to find high current boost converters in a small package.

You can step down as well, using RC hobby lipo packs or multiple lithium cells and higher voltages like 7.4V, 11.1V, 14.8V and use buck / step-down converters to get 5V. Something like one of these:

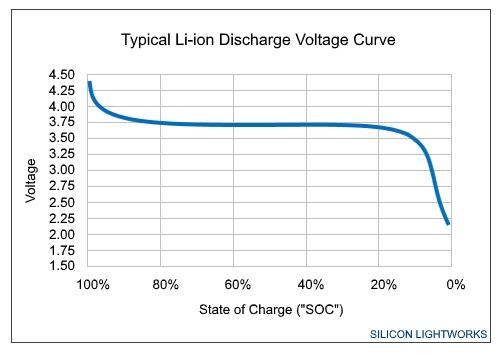

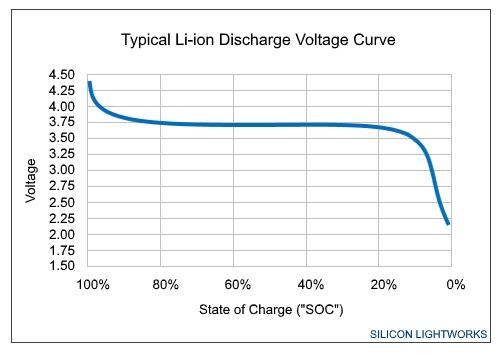

You will also want some way to monitor voltage and/or auto cutoff to avoid over draining the batteries.

Yet another option, most addressable LEDs are happy directly with 3.7V. Though there is less working margin for voltage drop over distance (you might find the colors dropping out further away from power), the plus side is this is more power efficient and the LEDs will run cooler. Both boost and buck converters have some power loss, and internally the addressable LEDs are burning power taking 5V and dropping it down to usable LED voltages.

Pixelblaze itself also runs fine on 3.7V, though may cut out near the last 10-20% of battery charge when voltages start dropping below 3.7V.

I also wanted to mention power distribution on the output expander. Normally I’d recommend the pro expander for higher current power distribution and fuses, but it might be too big for your project.

The 0.1" pin header connectors are rated at 3A. You can run a bit more with direct soldering, though there isn’t a ton of copper on the PCB connecting power to each output. You can increase that by supplying power right at the rows (there’s another column without data just for that) and bridging additional copper+solder along the power rows. Test it at full power, and keep an eye on temperatures. You can also route power external to the board, just be sure GND remains connected so that the data signals have a reference.

For safety, especially with higher power lithium batteries I’d add a fuse to protect against accidental shorts turning your fine artwork into a melty hazard.