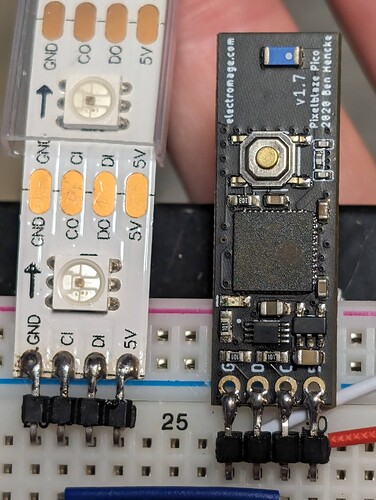

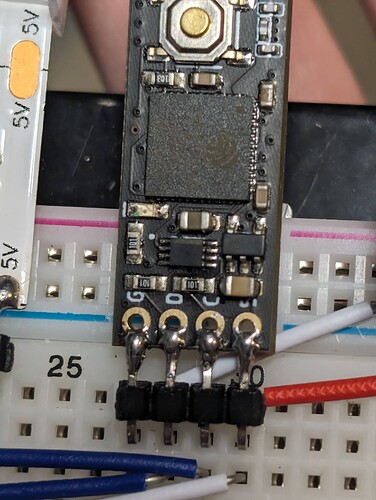

My LED project was on loan to someone, and when I received it back it no longer turned on. After close inspection, I could see that the Pixelblaze Pico inside was briefly turning on, lighting up dim orange, then bright orange, and then restarting after about a second. The device has 312 APA102 LEDs and is fed power at the beginning and end of the LED strip from a 5V 15A power AC adapter. Strangely, if I shine my flashlight at the strips as it turns on, a few of the LEDs will briefly flash on. When I try resetting the WiFi by pressing the button for 5 seconds, the orange light will begin blinking, continuing until I let go of the button before restarting again.

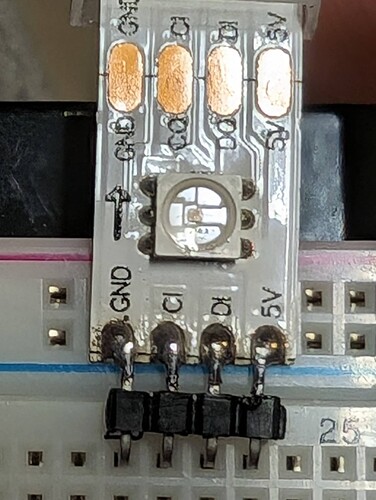

I inspected all of the solder points as best I could without removing each strip from the channels they are installed into, and they all looked intact as they were when the device was originally fit together. However, on the last strip at the end, there is possibly some discoloration (white flex-PCB slightly yellowed) around the SMD solder points of the LEDs.

So these are my questions:

- Shouldn’t the failsafe mechanism in the Pico disable the LEDs and allow itself to boot?

- Could this be a case of overheating/burning out some of the LEDs? What symptoms could I look for?

- What other troubleshooting steps would you recommend?