Hi @Nfiniteset ,

Welcome! Your project sounds awesome!

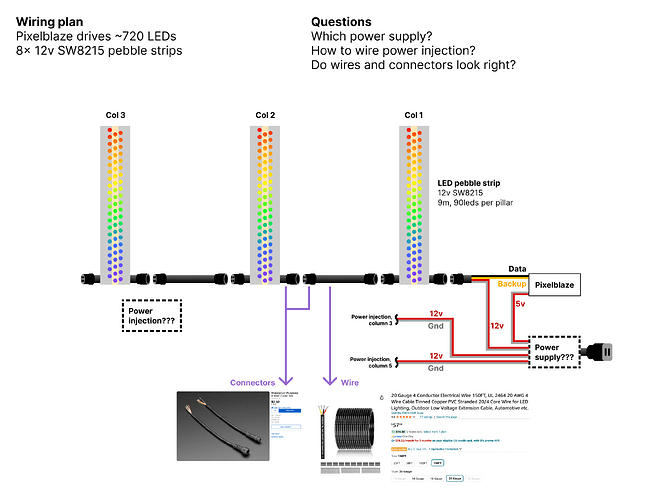

For power, have you considered solar + batteries for power? You can run WS2815 right off a 12V battery system. I’ve had good luck with both 12V and 24V systems using fairly affordable Renology chargers and panels, along with deep cycle gel batteries.

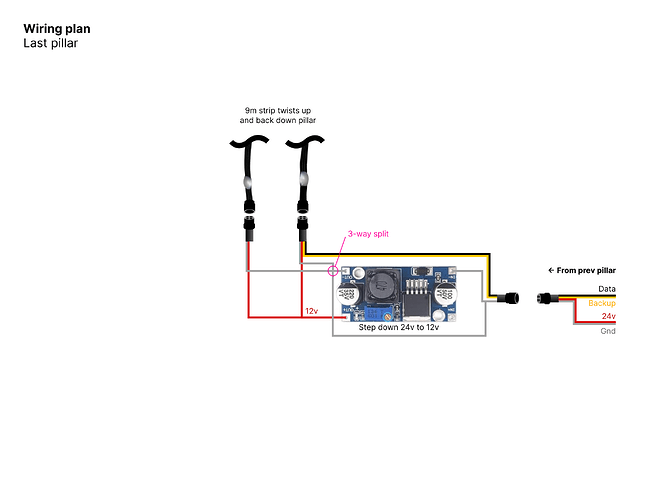

Adding on to what others have recommended, a 24V solar system with buck converters in each pole would probably improve your power efficiency (over 12V) since you end up losing less power in the wires.

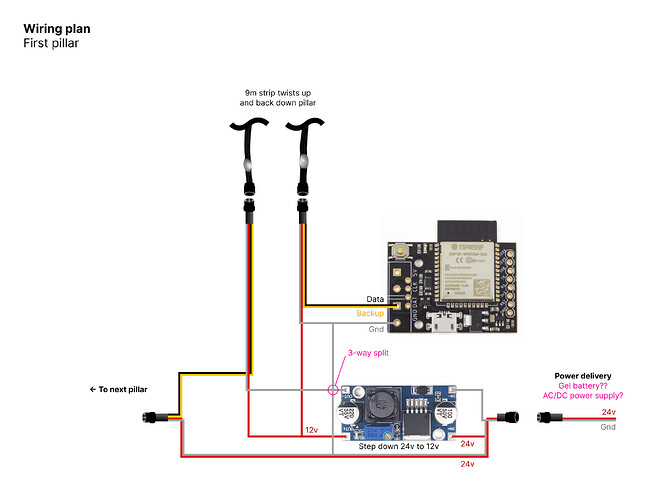

I would power your LEDs from both ends (run power to the top of the pole too, both - and +) for two reasons :

- This improves the output data signal for sending over a longer distance. Any voltage difference between the output and input LEDs only makes data signal issues worse, so its best to make that the same voltage by wiring power to both ends.

- That helps with voltage drop along the strip, and would let you drop the working voltage near the minimum, improving efficiency.

WS2815 draw around 13ma on max brightness regardless of color, so figure on 1.17A per pole. They will also work just as well at 10V, so if you are converting down from 24V+ you can eek out even more efficiency by tuning your buck converter to output 10V or so.

Something like these should work OK:

The key trick with these is that you want to adjust the voltage before connecting to LEDs, you don’t want to accidentally over-voltage your LEDs. Connect a multi meter to the output, power the input, and adjust the small blue pot with a tiny screwdriver. These will get hot with high currents, but 1A should be OK.

These kind of converters are not great for Pixelblaze itself, for that I would recommend a mini-buck for 12V systems.

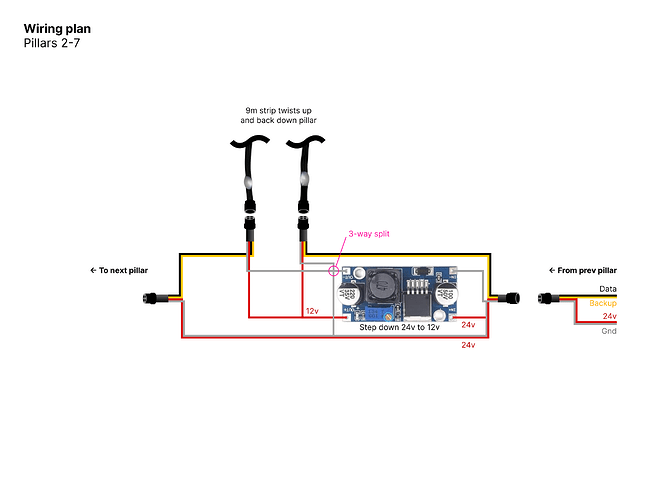

For data signal integrity, your data lines have 16 ft between the top of the pole and the next pole (assuming you wired them bottom up, but it would be 16 ft either way). Thats marginal. It would probably work, but there’s a chance it would flicker, which is the WORST, so I would design to avoid that if possible.

If you can drop that down to 8ft, you should have no problems. One way to do that is to wire from the top to a single LED in the base right before the output. This LED would act like a repeater and “reset” the distance. It would still take a pixel worth of data though, for most things that wouldn’t impact animations in any great way. If it was visually distracting, you could hide it.

Another way to do that would be to change how you wrap the pole. Use half to run upward, and the other half to run downward. That would be a little more complex to pixel map, but would be another way to get the output and input at the base to minimize distance and require no extra LEDs.

![]()