I’ve noticed that one of the 16x16 flexible LED Matrices (NeoPixel style) that I’m using has already got a fritzy solder connection. Since I’m distributing a lot of these & they’ll be carried around in backpacks, any ideas on how to de-stress some of this wiring? Hot Glue over solder joints & at first part of wire gluing to the matrix’s backing? Heavy packing tape over the joints & first bit of wire? Recs really appreciated.

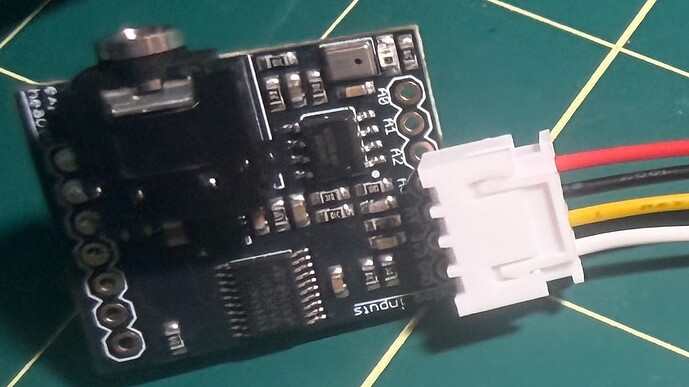

Also: I am a genuinely terrible maker., which I suppose makes my students not feel so bad when they make mistakes Despite knowing “measure twice cut once”, I regularly solder things wrong, backwards, etc. And here is today’s example. I soldered the JST Xh connector to the wrong side of the sensor board ![]() Rather than risk the nastiness of trying to desolder this four pin connector, I thought I might just ignore it for now & solder the connector on the proper side / orientation. Is this OK? Any other suggestions?

Rather than risk the nastiness of trying to desolder this four pin connector, I thought I might just ignore it for now & solder the connector on the proper side / orientation. Is this OK? Any other suggestions?