Hi all, diving head first into the Pixelblaze world with a project just barely beyond my current skill set, would really appreciate some expert eyeballs on it to make sure I’m thinking things through properly. At a minimum, can guarantee it’s a spectacularly cool project!

Some background:

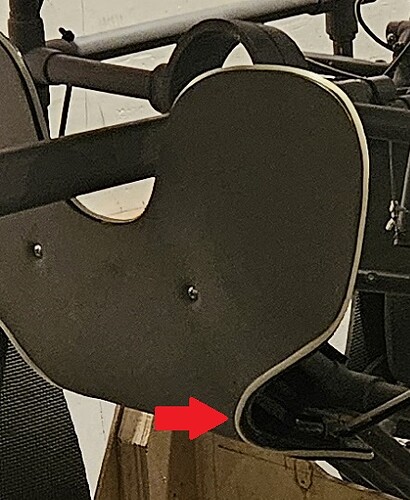

I have a delightful dinosaur puppet currently covered in ~60m of non-addressable COB LED strips, powered by 2-3 9Ah 12V batteries.

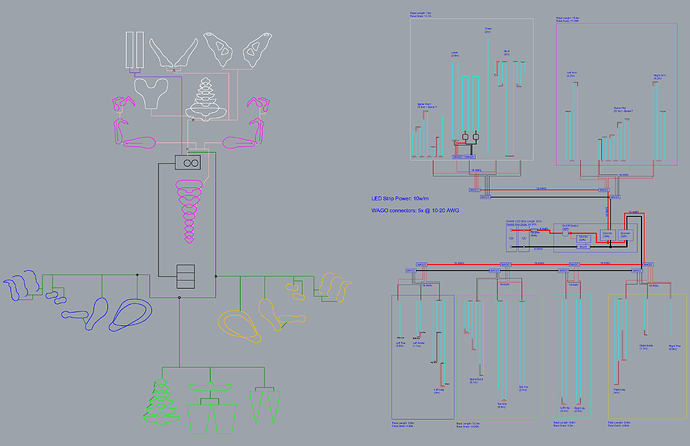

The wiring has been mercifully simple since it’s only split into two channels, and 95% of the lights are on a single channel (everything but the teeth); all I’ve really had to consider was the total length of strips connected in series, which are limited to <5m each to minimize power injection needs. On paper, the lights are 10w/m and the entire system should draw 44A max, but in practice it only draws 17A max, which I dial down to ~3A via PWM dimmers for optimal brightness (zero heat issues from lights or wires, so presuming the delta is due to collective voltage drop). All the wiring was planned for the higher amperage, so the mainline that each segment branches off of is 10awg (downsized from the original 8awg), with 18-20awg leads or connectors branching off to each strip segment via wago hubs.

Main interest in upgrading to addressable LEDs is uniform color changes. However, I’m discovering wiring a dozen channels of addressable LEDs would be far easier than wiring a dozen RGB strips, and there’s definitely a possible world where some programmed animations (and even some x,y,z pixel mapping) might be called for, hence leaning into Pixelblaze.

General plan:

Want to make sure I’m thinking through the hardware, power, and wiring aspects of this correctly.

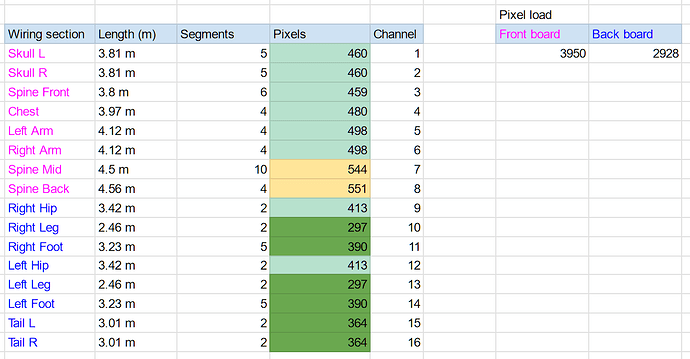

For the lights, I’m looking at these individually addressable 12V 120 LED/m WS2811 strips, with a power draw of 14.4w/m. The 120/m density seems like the sweet spot between enough lights to look gapless inside a silicone diffusion tube (or half of one at least), without being an excessive amount of pixels to drive. Still puts me in the ~7,000 total pixel range. Also considering these 12V 96 LED/m WS2811 strips, the diffusion should still look adequate but the pixel resolution drops considerably (3 LEDs per pixel, ~2,000 total pixels) for the same 14.4w/m power draw. Does either sound inappropriate on its face, either because 7,000 total pixels is too unwieldy, or because 96 LEDs/m / 32 pixels/m is a disappointingly low density or resolution?

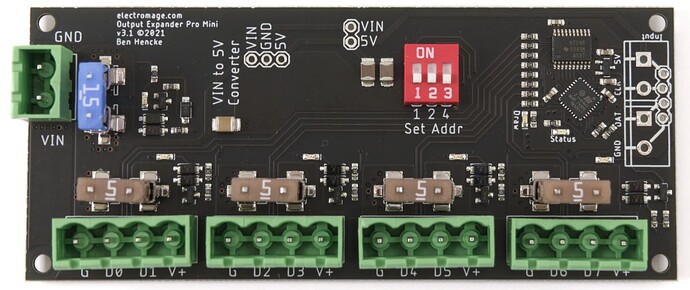

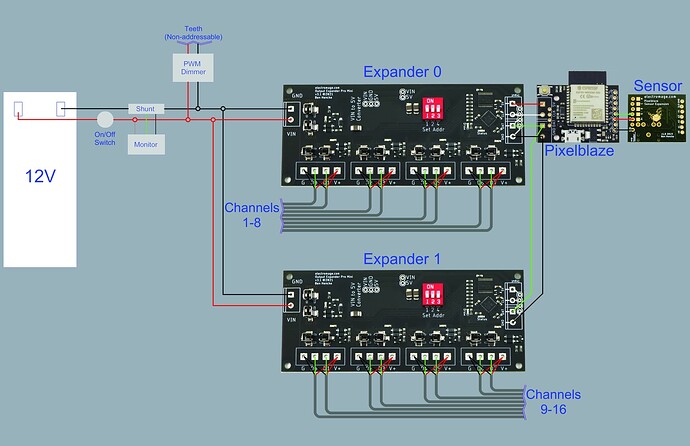

For the hardware and power, planning a Pixelblaze V3 + 1-2 expander boards + mini buck for powering the boards. I’d like to retain the current 10awg mainline for powering the strip segments, feel like it’d be a rat’s nest of wires otherwise. Are the regular expanders sufficient if I’m not powering the strips off the board (so the 15A v 3A power difference is irrelevant), or is there another reason to consider using 1-2 pro boards instead? Any additional considerations here given everything is running off 12V batteries?

Lastly, curious where/how I’d start thinking about pixel mapping this beast. I could get pretty far doing a 2D map using a tool like this Google Sheets-based mapper with a top-down, roadkill-style layout, but there are enough overlapping pieces that thinking in 3D could really dial things up to 11. Since I don’t have much of a coding background, is there a way to, I don’t know, take a CAD model of the LED layout and covert that into a x,y,z pixel map? Or something else? I couldn’t make heads or tails of the tutorial documentation on pixel mapping, so hoping this isn’t completely outside the realm of possibility.

Feels good to get all that off my chest. Really looking for insights on the light strips and Pixelblaze hardware options, and making sure I’m not overlooking something that might cause a fire (since, you know, I’m wearing all of this). Thank you much!